Week 3 - Biomaterials

Engineers need to consider the properties of the materials we use. Bio-engineers do the same thing.

What are Biomaterials?

Biomaterials are any synthetic or natural material that comes into contact with a biological system. The term biotolerated implies three things about a material:

- It is not rejected by biological systems (ie: the immune system)

- It does not evoke adverse reactions (toxic, carcinogenic) or worse (death)

- It does not interfere with or modify biologic processes such as wound healing

In addition, a biocompatible material also promotes healing and tissue integration.

GoreTex is an interesting material used in types of clothing and outdoor gear. See more here. Essentially, it's a material that skin can grow around. It requires that the immune system doesn't attack it, but scientists implanted proteins in the material where as cells grow in, you don't get scar tissue from the immune system.

Common Types of Biomaterials

There are many common types of biomaterials which we will look at:

- polymers

- metals

- ceramics

- composites

Each one has different features:

- Strength and stiffness

- Creep properties

- Fatigue and wear characteristics (cyclic loading)

- Conductivity

- Environment

Polymers

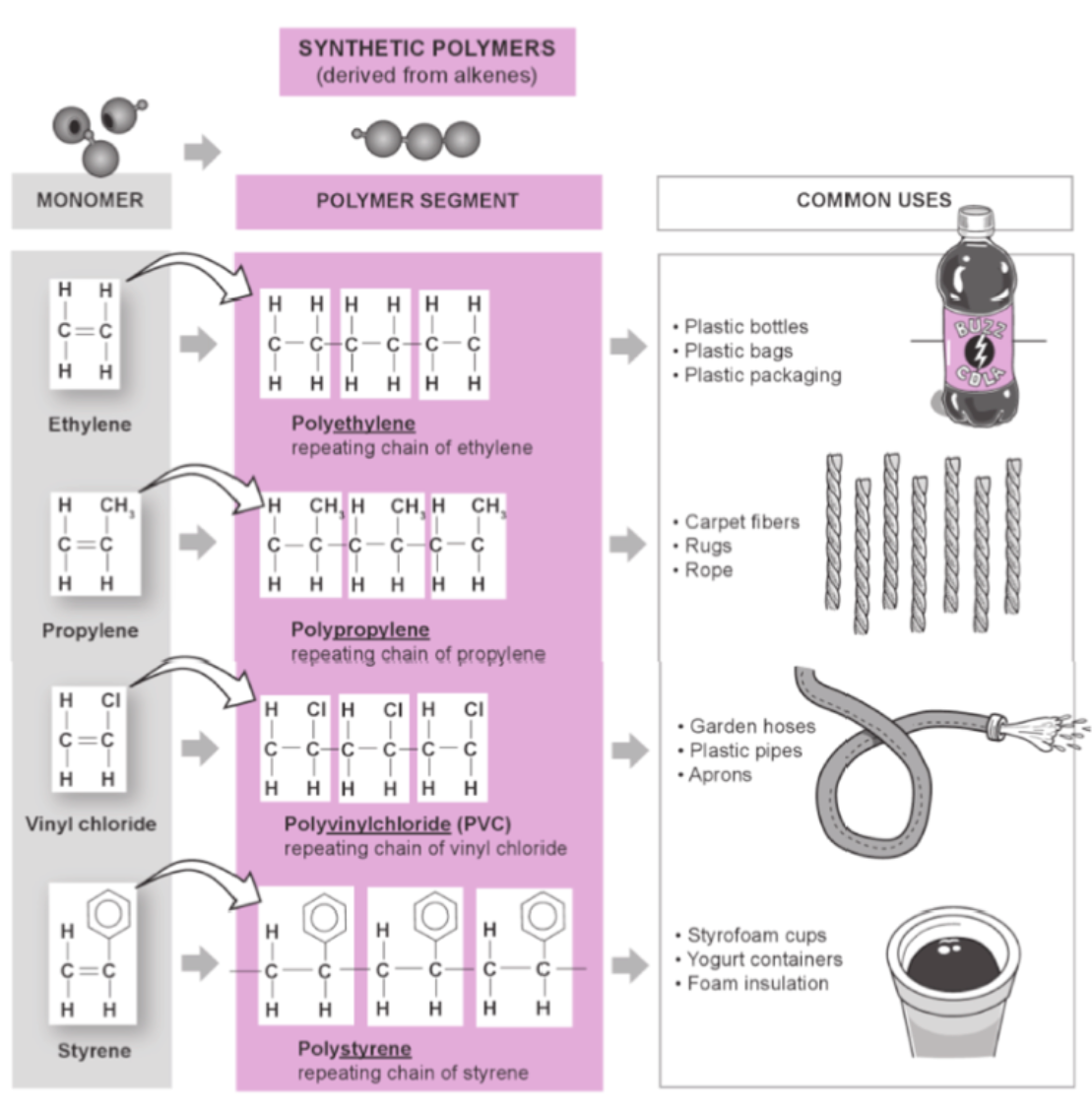

Polymers are macromolecules; large structures made up of thousands of repeated smaller units (monomers). The monomers attach together end-to-end or side-to-side.

Polymers are either synthetic or natural. For instance, spider silk is a natural polymer stronger than steel; however, it is not easy to produce a synthetic version of spider silk.

Metals

There are ferrous metals (metals with iron, usually alloys of it) and non-ferrous metals (without iron, such as aluminium).

Nonferrous metals are often specified in engineering designs for structural applications requiring reduced weight, higher strength, nonmagnetic properties, higher melting points, or resistance to chemical and atmospheric corrosions.

These are often used to repair bone fractures (ie: implants).

Ceramics

Ceramics are inorganic, non-metallic materials. Metal oxides like FeO or

- hardness

- chemical inertness

- resistance to corrosion

- low cost of fabrication

They are usually more brittle than metals while being similar in strength and compression. This is due to the minute crack ("Griffith cracks") that they form under stress.

They are usually formed from compacting powders into a cohesive body. In biology, they are mostly used n orthopedic and dental implants.

Composites

Composites are materials formed from a mixture of two or more components for a material with a mix of these properties.

Most composited are formed of two phases:

- Matrix: continuous phase material; usually less stiff and weaker than the reinforcement

- Reinforcement: fibers, fabric, whiskers, or particulates are embedded in the matrix; discontinuous and are stronger and stiffer than the matrix

Comparing Types of Materials

| Material | Advantages | Disadvantages | Main Applications |

| Polymers: Silastic, Teflon, Dacron, Nylon, PMMA, Polyethylene, Polypropylene, Polytetrefluorethylene | Easy to produce, low density | Low mechanical resistance, easily degradable | Sutures, arteries, veins, cements, artificial tendons, teeth, ears, nose, heart valves, lenses, testicles and breasts. implants |

| Metals: Steels 316, 316L, Vitallium, Silver, Tantalum Cobalt F-75 and alloys of: Ti, Cr+CO, Cr+Co+Mo |

Ductility, high mechanical resistance to wear and shock | Low biocompatibility, corrosion in a physiological environment, mechanical properties very different from those of biological tissues | Staples, plaques and wires, articulation prosthesis, tooth implants, penis implants, skull plaques and mesh for face reconstruction |

| Ceramics: Aluminum oxides, calcium aluminates, titanium oxides, calcium phosphates, carbon, Bioglass | High biocompatibility, corrosion resistance, high resistance to compression, inert, low thermal and electrical conductivity | Low impact resistance, properties difficult to reproduce, difficulties in processing and fabrication | Dental parts, coatings, bone fillings, endoscopy, otologic implants, medical tools and equipment |

| Composites: Metals with ceramic coatings, materials coated with carbon | High biocompatibility, corrosion resistant, inert | Lack of consistency and difficult to reproduce during fabrication | Heart valves, knee implants, artificial articulations, hip implants |

| Natural Materials: Colagen, human tissues, hialuronic acid, grafts |

Availability in the human body, biocompatibility | Possible rejection by host | Increase or substitution of hard and soft tissues, cornea protectors, vascular grafts, tendons and ligaments, heart valves, ophthalmologic lubricants, substitution of synovial fluid |

Osteoarthritis and Joint Replacement

osteoarthritis (OA) is a degenerative joint disease. In normal joints, a firm rubbery material called cartilage covers the front end of each bone. It provides a smooth, gliding surface for joint motion and cushions between bones. Under OA, it breaks down, causing pain and swelling. Over time the bones may break down and develop growths called spurs. Over more time, the cartilage breaks away and the bones damage each other even more.

There's no cure for OA, but there is treatment via joint replacement surgery. We can replace the cartilage where missing using these biomaterials.

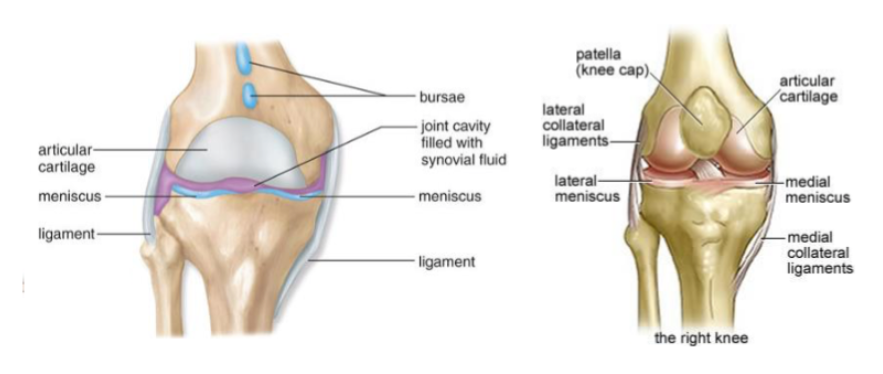

The knee joint (shown at right) connects the femur in the upper leg to the tibia in the lower leg. In between these bones is the meniscus, a shock-absorbing tissue, and articular cartilage lubricated with synovial fluid. The joint is surrounded by strong ligaments which stabilize the motion of the knee. When healthy, the lubricated cartilage has a coefficient of friction (0.001-0.005) much lower than that of the metal blade of a skate on ice (0.02).

An artificial knee must be designed to support the weight of the body while allowing it to move smoothly. We require:

- A support material: one that's hard and stiff (titanium or an alloy of cobalt-chromium)

- Shock absorption: polymer disk (polyethylene)

- Low Friction Movement

Total Hip Replacement

Similar to knee replacement, hip replacement occurs from OA. An artifical hip is implanted to help relieve the suffering from OA. There's three primary designs:

- Metal-on-polymer: a metal ball and socket made of polymer; known to war faster

- Ceramic-on-ceramic: use a ceramic material for both ball and socket; least wear but possibility of internal shattering (usually ceramic-on-polymer is used instead)

- Metal-on-metal: lowest wear rates and mechanical failure; used the lowest though

- The debris on two metal surfaces causes failure later on (very quickly).

- Debris has micro/nano particles of cobalt chromium which is toxic to the body

There's also the concept of stress shielding:

Essentially, it is the weakening of the bone by having the metal implant help cover a lot of the stress the bone normally has to deal with. As a result, strong bone tissue just dies off from not being used, weakening the surrounding bone as a result (largely due to having less bone material used on the hip or leg or whatever).